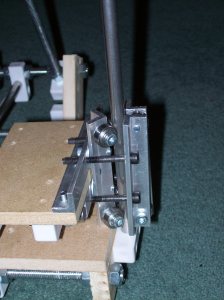

The first extruder head that my Dad made for me a while back had a number of pitfalls

- It was difficult to drill a 0.5mm hole (he broke several drill bits trying to make it)

- The resistor wasn’t a very tight fit in the aluminum block.

- The thermistor was attached using Thermic Seal which despite being rated to 1250 °C would crumble and fall out.

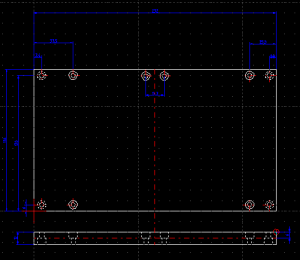

So my Dad kindly offered to make a new and improved version based on some specifications and designs that we came up with together.

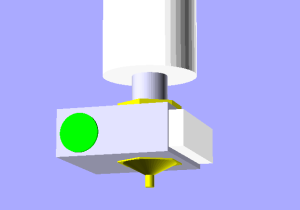

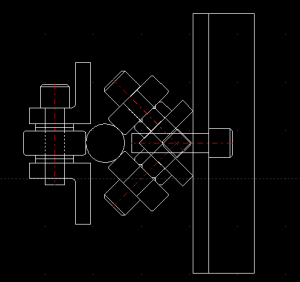

Rather than try to drill a 0.5mm hole I bought an already fabricated nozzle. Quite a few companies make these now specifically for reprap printing machines including Makerbot, ReprapStores, MakerGear and ReprapSource.

My Dad turned down the nozzle to a round insert that could be put directly into the aluminum heater block. The other addition was a PTFE thermistor clamp to hold the thermistor on using two m3 screws rather than glue.